CORRUGATED STAINLESS STEEL HOSES

AISI 321 and AISI 316 metal hoses

CORRUGATED STAINLESS STEEL HOSES

The Sae-inox metal hoses with parallel corrugations, with no joints or interlocks, guarantee perfect pressure tightness and excellent flexibility guaranteed by the deformation of the continuous walls. They are manufactured, depending on the operating conditions, with one or two braids in stainless steel, in accordance with ISO 10806 standard requirements, while the fitting’s welding process is EN ISO 9606-1 certified.

Our corrugated stainless steel hoses are used for conveying fluids of various kinds, such as vapours, gas, neutral fluids, acids, alkalines or solvents, and in the harshest operating conditions, provided that the conveying takes place on the same level and at a temperature of between -270°C and +600°C.

MODELS AVAILABLE

The range of corrugated metal hoses includes:

- Hoses made of AISI 321 stainless steel, in accordance with the International ISO 683/13 Grade 15 standard, the ASTM A240 Grade 321 standard and the DIN WN 1.4541 standard.

- Hoses made of AISI 316 TI stainless steel, on request, in accordance with the International ISO 683/13 Grade 21 standard and the DIN WN 1.4571 standard.

- Hoses made of AISI 316 L stainless steel, on request, in accordance with the International ISO 683/13 Grade 19 standard, the ASTM A240 Grade 316L standard and the DIN WN 1.4435 standard.

CORRUGATED HOSE COVERS

Our corrugated stainless steel hoses can be reinforced with one or two braids in AISI 304 austenitic stainless steel, in accordance with the ISO 683/13 Grade 11 standard, the ASTM A 580 Grade 30 standard and the DIN WN 1.4571 standard. On request we can also supply AISI 316 TI austenitic steel wire braid covers in accordance with the ISO 683/13 Grade 21 standard and the DIN WN 1.4571 standard.

STAINLESS STEEL HOSE WELDING

The welding of corrugated hoses is carried out with TIG welded end fittings in carbon steel or stainless steel.

TESTED METAL HOSES

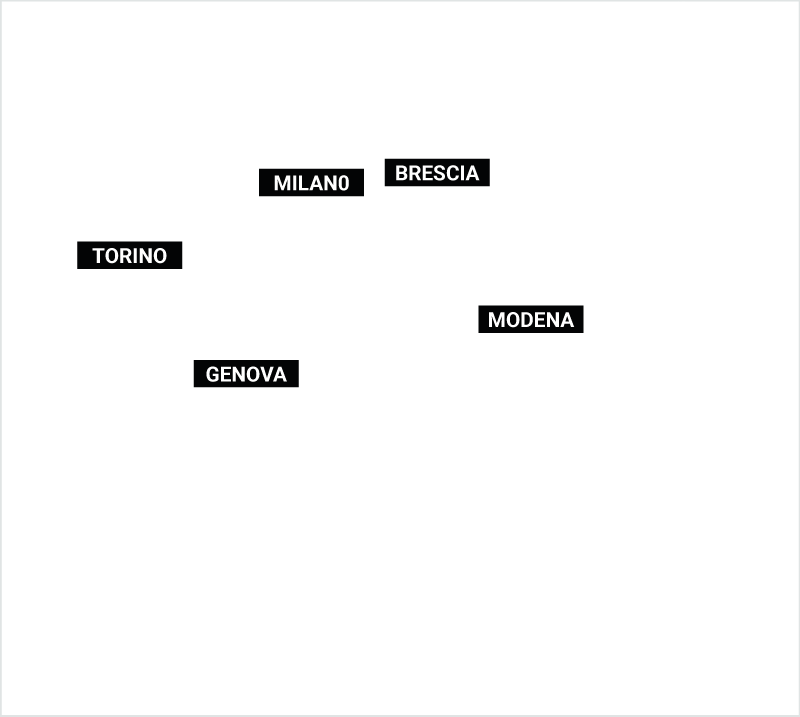

The corrugated AISI 321 and AISI 316 hoses are 100% tested at our plant facility in Adro, near Brescia, with strict pressure testing using specially designed test equipment to guarantee the integrity of the same. Strict process controls help to maintain superior quality standards and their compliance with the new international directives, including Directive 2002/95/EC, which restricts the use of polluting materials.

RANGE OF APPLICATION

Hydraulic systems are present in almost all industrial machines that handle fluids during the various processes, such as machine tools, plastic moulding systems, industrial washing plants, chemical plants, steel plants, cement works.

In these sectors our technical support plays a key role in the design and realisation of customised hydraulic units, but also in the after-sales support and assistance services to machine manufacturers, maintenance firms and end users with technical advice, testing and inspection and scheduled cleaning services.

For the industrial refrigeration sector, in addition to supplying fittings, pumps, motors, and filters, we specialize in providing stainless steel tubes that can be customized and connected in our welding center.

Moreover, for the industrial refrigeration sector, we provide a post-sales service that includes testing and cleaning operations, technical support both at our headquarters and at the customer’s site, and a dedicated logistics system through the Kanban management.

We support machinery manufacturers, maintainers, and users by providing top brand components, motors, and pumps, as well as tailor-made solutions to make drilling systems, mining machinery, and onshore and offshore oil extraction systems more efficient.

For the mining industry, we also offer our flanging center, perform testing and component customization, and implement the Kanban logistics system to ensure timely and consistent supplies.

Our expertise in the hydraulic sector allows us to work with manufacturers, maintainers, and end users of all types of vehicles, from components for the railway and aerospace sectors to hydraulic solutions for agricultural and industrial vehicles, special vehicles, and military vehicles.

In addition to the supply of components such as tubes, fittings, motors, pumps, and filters, we offer technical support, component customization, Kanban logistics, and a timely after-sales service that includes testing, cleaning, and scheduled maintenance for the transport sector.

Inside our warehouse we have a wide range of hydraulic components and devices, which are used in construction machinery, robotic systems, and industrial plants in general.

Thanks to the Kanban logistics system, we can also guarantee to manufacturers, maintainers, and users in this sector a constant and punctual supply of the most commonly used components, and through our technical office, we provide them with all the pre- and post-sales support they need.

Increasing energy efficiency through the combination of intelligent and appropriate components allows for easy acquisition of all relevant data on a system, providing the basis for integrated energy management.

Thanks to our collaboration with world leaders in hydraulics, we can offer solutions through the application of state-of-the-art components.

The hydraulics, in logistics, are applied in all transport, storage, control, robotic interactions operations.

Thanks to the brands we deal with and the specialization of our team, we can propose solutions to achieve the set objectives.

CHOOSE THE VERY BEST FOR YOUR HYDRAULIC SYSTEMS.

CHOOSE SAEFLEX.

CHOOSE SAEFLEX.

Complete this form to get in touch with our technicians trained to recommend the most suitable solution to meet your demands.